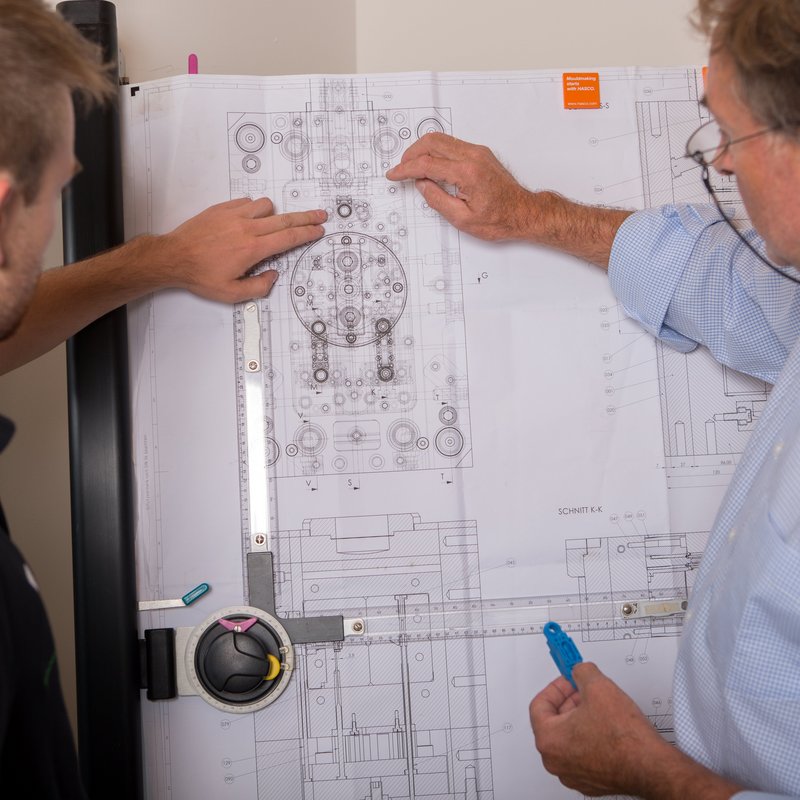

Product development

In the field of product development we will give you important impulses in the early phase of your project. Therefore we certified our consulting competencies according to ISO 9001: 2015.

We will support you fast and reliable to convert your ideas into a technically and economically succesful plastic product.

Idea

We develop and implement innovative products - from single components to complex assemblies. We give to you support with our network as a competent partner for all phases of the development process, from the initial idea to the start of production.

If needed, we can realize your idea in a CAD design, for this we work with the widely popular CAD system Solidworks.

Based on your idea we will work out together the product specifications and the project plan.

We are at home in the development of components in the fields of automotive, electronics, medical technology, packaging as well as sports.

Our goal is to deliver a result that convinces you in every way.

Feasibility

To keep risks and costs as low as possible in the development of your products, calculations are presented transparently and openly and, if required, a production and process FMEA is created.

Additive manufactured prototypes for the initial implementation and rapid iteration of your idea can be carried out in-house within a very short time. This allows us to work together, iterate and confirm the feasibility of the design as quickly as possible.

If 3D printed samples are not meaningful enough, we also offer small series injection molding from prototype tools to validate the prototypes in original material.

Implementation

Additive manufactured prototypes for the initial validation of your idea are standard for us.

For this purpose, we have industrial FDM printers as well as resin-based 3D printers at our own disposal.

We are able to support you in topics of public funding for the development of new products, in order to keep the entry barrier in the product realization as low as possible.

In the area of assembly of components and finishing, as well as gluing and sealing of your products, we can support you in the realization and industrialization with our know-how.

In doing so, we can remain competitive with larger companies through reliable and cost-effective partners.

DE

DE EN

EN